Eaton Gas/Liquid Separators

FLOAT DRAIN TRAPS

Eaton drain traps efficiently handle, without loss of line pressure, the draining of condensate removed from air or gas lines by separators of the condensate which accumulates in storage tanks or at drip points. These traps are capable of removing up to 2800 pounds of condensate per hour and work with pressure differentials from 5 psi up to 250 psi.

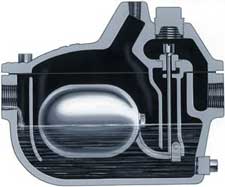

Model 90-AC and 95-AC Float Drain Trap

Available in cast iron or cast stainless steel for 0 to 500 psi service. Loss of air or gas is prevented by a positive water seal. They have a straight-through design. Internal parts, including valve and seat, are corrosion-resistant, non-magnetic stainless steel. All working parts are attached to the base for easy removal and inspection. A side inlet/outlet configuration is available for iron, carbon steel and stainless steel traps.

Model 230-AC

Available in cast iron for 0 to 125 psi service. Ideal for use where gummy emulsions or cylinder lubricants make other traps inoperative. They feature a vertical inlet, downflow discharge design. Ample float power and large outward-opening discharge valve prevent loss of pressure. Internal parts are stainless steel, including non-magnetic valve and seat. Working parts are attached to the cover for easy removal without disconnecting the trap from the line. No priming is required. For low temperature applications a heater is available as an option.

Model 350-AC

˝THREE TRAPS IN ONE˝ is the basic principle of these ball float traps. Three valves open and close progressively as condensate volume varies. As float chamber water level rises, the float lies deep in the water until its buoyancy overcomes the opposing line pressure and snaps the valve wide open. When closing, as each valve approaches its seat, the line pressure snaps it tightly closed. These traps have cast iron bodies, and stainless or copper internal parts. A by-pass thermostat is standard.