Bag Filter Systems for Liquid

Eaton improves oil recovery system in Western Australia

Background - A challenge faced by a petroleum producer in Western Australia was how to bring oil to the surface when there was insufficient pressure in the crude oil reservoir below ground. A water injection system, where water is pumped back into the reservoir to increase pressure and thereby stimulate production was installed. Normally only 30% of the oil in a reservoir can be extracted, but with water injection that percentage increases. Because of the desert location the water in the system has to be filtered and recycled to keep consumption to a minimum. Over time the water flow rate required by the application exceeded the capacity of the filtration system.

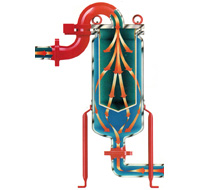

Solution - The existing filtration system consisted of “home-made” filter bag housings with 50 micron filter bags that fed into 10 micron cartridge filters. This system could not provide an adequate flow of water for the application and because of the cartridges, the operating costs were high. Eaton’s solution was to completely replace the existing filtration systems with a bank of six TOPLINE™ Filter Housings with 10 micron SENTINEL® Filter Bags. Differential pressure gauges were fitted to the filter housings to indicate when filter bag changes were required.

Results - The Eaton system, with a design flow rate of 200 cubic meters per hour was more that adequate to handle the applications requirement of 100 cubic meters per hour and would be able to meet future requirements as well. The system operators were pleased because the new system was easier to operate and maintain than the older one. And, without the cartridges, it was less costly. After running successfully for several months the customer began looking at other locations where this system or a similar one could be used.

“Eaton’s solution eliminated the need for inefficient, costly stage and cartridge filtration”